Demolition sites are synonymous with thick dust clouds, which not only violate environmental regulations but also pose severe threats to workers’ respiratory health and nearby residents’ daily lives. Traditional dust control methods like manual water spraying are inefficient, waste water, and fail to cover large areas or target dust hotspots. In this context, the fog cannon machine emerges as a game-changer, offering a professional, efficient, and compliant solution for demolition dust suppression.

What makes fog cannon machines ideal for demolition scenarios? Unlike temporary fixes, they are engineered to tackle the unique challenges of demolition dust. Equipped with high-pressure pumps and precision nozzles, these machines produce ultra-fine mist particles (30-50 microns) that perfectly match the size of demolition dust particles. The mist wraps around dust particles, weighing them down and preventing them from spreading—achieving a dust reduction rate of over 90% in minutes.

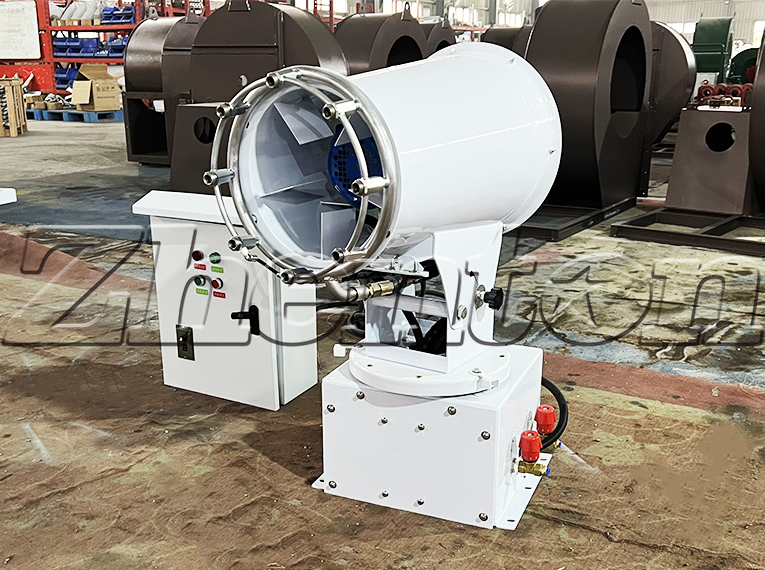

Mobility and adaptability are key advantages. Most fog cannon models are mounted on trucks or trailers, allowing operators to chase dust hotspots such as building teardown areas, debris loading zones, and conveyor belts. With a coverage range of 30-120 meters, they can cover the entire demolition site, even in large-scale projects. Additionally, adjustable mist intensity and angle enable targeted suppression, avoiding waterlogging of debris or interference with construction machinery.

Energy efficiency and compliance further enhance their appeal. Modern fog cannon machines save up to 60% water compared to traditional spraying methods, reducing operational costs. Equipped with low-noise motors, they minimize disturbance to surrounding communities. For contractors, using fog cannon machines ensures compliance with strict environmental standards, avoiding fines and reputational damage.

Real-world applications prove their effectiveness. A construction team in a major city used fog cannon machines during a factory demolition project, reducing on-site dust concentration by 95% and eliminating resident complaints. Workers reported improved comfort, and the project progressed smoothly without dust-related delays.

When choosing a fog cannon machine for demolition, prioritize durability (corrosion-resistant materials for harsh environments), coverage range, and ease of operation. Opt for models with remote control functionality for safe, convenient operation from a distance.

In demolition projects, dust control is no longer a hassle. The fog cannon machine transforms chaos into order, safeguarding health, ensuring compliance, and boosting efficiency. For contractors committed to responsible and efficient demolition, it is not just a choice—it is an essential investment.

Contact With Us

If you have any questions please fell free to contact with us.