On the ancient Silk Road, only the resilient survive. Uzbekistan’s continental climate presents a formidable challenge to industrial machinery: blistering summer highs of over 50°C in the Kyzylkum Desert and bone-chilling winter lows reaching 20°C. For a Dust Suppression System to be effective here, it cannot be a standard “off-the-shelf” product. At Zhenton, we have re-engineered our technology to withstand these extremes, ensuring that your investment remains operational when you need it most.

“Quality is remembered long after the price is forgotten.” — Henry Ford (A testament to Zhenton’s commitment to long-term engineering value over cheap, short-term fixes).

The primary enemy of a Dust Suppression System in Central Asia is thermal stress. During the “Chilla” (the 40 hottest days of summer), standard motors often overheat and trip. Zhenton units are equipped with Class H insulation motors, capable of continuous operation in ambient temperatures up to 50°C.

Conversely, for winter operations, our systems feature an integrated anti-freeze heating kit and an automatic drainage valve. This prevents water from freezing inside the manifolds and damaging the precision nozzles, allowing for a rapid “start-and-stop” capability even in the heart of a Tashkent winter.

Uzbekistan’s winds are not just air; they are abrasive carriers of sand and saline particles.

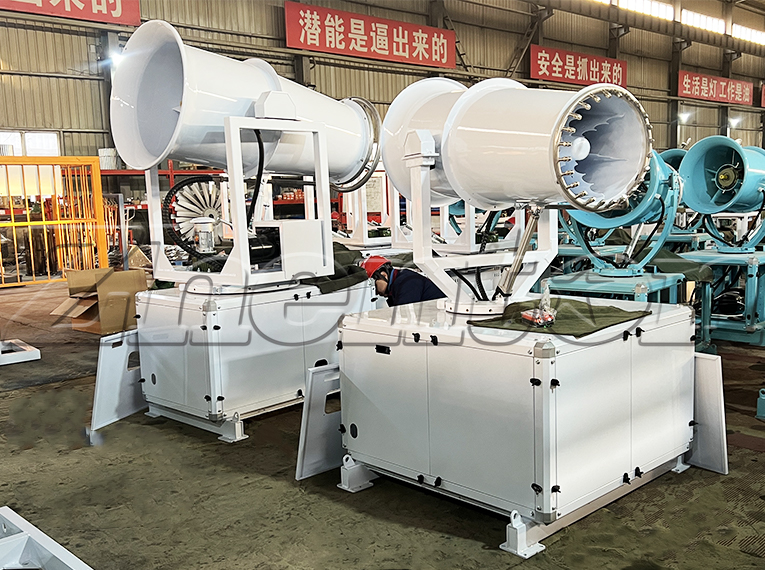

Advanced Surface Protection: Every Zhenton unit undergoes a 3-stage coating process, including a C5-M marine-grade anti-corrosion layer. This ensures the chassis and turbine housing remain rust-free for over 8 years, despite the corrosive nature of salt-laden dust from the Aralikum region.

Sand-Proof Filtration: Our 300-mesh stainless steel filtration system ensures that even if water is sourced from open canals or silty municipal lines, the internal high-pressure pump remains protected from abrasive wear.

In the heavy industrial zone of Navoi, a large-scale mineral processing facility required a Dust Suppression System that could operate xx/7 in a high-heat, high-dust environment. Previous equipment from other suppliers had failed within xx months due to motor burnout and nozzle clogging.

Zhenton installed a fleet of 30 heavy-duty units. By utilizing our specialized “Sand-Shield” motor enclosures and high-torque rotation gears, the facility reported xx% uptime over the first year. The maintenance team noted that the Zhenton units required 98% less servicing than their predecessors, Significantly optimizing operational expenses year-over-year.

A: With a standard preventative maintenance schedule, our systems are engineered for a service life of 10 to 15 years. The use of galvanized steel and high-grade polymers ensures the structure outlasts the project’s lifespan.

A: No. All exposed seals, hoses, and electrical cables used in Zhenton systems are UV-stabilized. We use premium materials that do not become brittle or crack under the intense Central Asian sun, maintaining their flexibility for xx years.

A: Each Zhenton Dust Suppression System is designed with a “Safe-Park” mode. Sensors can detect high wind speeds, automatically rotating the fan to a neutral position and sealing the intake to prevent internal sand accumulation, protecting the aerodynamic balance of the blades.

Contact With Us

If you have any questions please fell free to contact with us.