When the sweltering heat of 40℃ sweeps across open-air material yards, construction work is forced to come to a halt. Concrete dries quickly, equipment malfunctions frequently, and the risk of workers suffering from heat-related issues surges. Traditional cooling methods prove ineffective, and issues like delayed project timelines and out-of-control costs have become pain points in the industry. Smart mist cannon machines, with their technological breakthroughs, can reduce the temperature in material yards by 8℃, emerging as a powerful solution for construction in high-temperature environments.

In extreme high temperatures, the unloading time of concrete mixing trucks increases by 30%, and the failure rate of heavy machinery doubles. In a certain infrastructure project, due to equipment malfunctions caused by high temperatures, the weekly shutdown time exceeds 20 hours, resulting in losses of 500,000 yuan. Workers are prone to heatstroke and make more operational mistakes. The accident rate during high-temperature operations is three times that in normal temperature environments. To catch up on the project schedule, companies have to bear the premium costs of nighttime construction. A municipal project paid a penalty of 2 million yuan due to a 15-day shutdown.

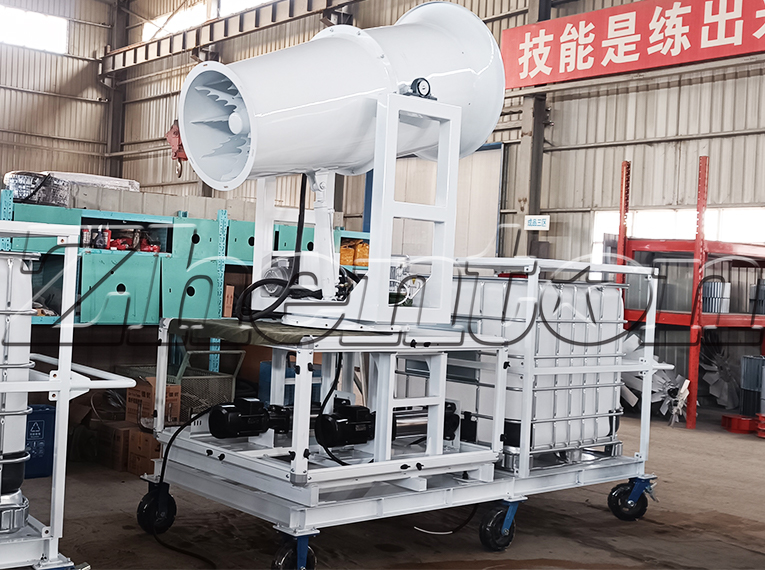

Smart mist cannon machines, with their micron-level atomization technology, can transform water into fine water mist with a diameter of 20 – 50 microns. In a 40℃ environment, they can reduce the local temperature in material yards by 8℃. A mist cannon machine with an 80-meter range can cover an area of 10,000 square meters. Equipped with temperature and humidity sensors and an intelligent control system, these machines automatically start when the temperature exceeds the set threshold and stop when it reaches the safe range. With APP remote control, they can save 30% of energy. Additionally, these machines have functions such as dust suppression and moisture retention, and some models support disinfection, offering multiple functions in one device.

After introducing 4 mist cannon machines with a 100-meter range in a 30,000-square-meter high-speed railway material yard, the temperature dropped to 32℃, equipment failures decreased by 60%, construction efficiency increased by 40%, the project schedule was advanced by 10 days, and costs were saved by 3 million yuan. After a port material yard started using these machines, the dust concentration decreased by 70%, meeting environmental protection standards. It saved 500,000 yuan in costs annually and increased the loading and unloading efficiency by 25%.

When purchasing smart mist cannon machines, key parameters such as the range are crucial. Select the range according to the size of the material yard, and prioritize devices with smaller atomized particle sizes. Confirm the precision of sensors and remote control functions in the intelligent control system. Choose brands with quick after-sales response and a long warranty period to ensure the stable operation of the equipment.

Smart mist cannon machines, with their technological innovation, solve the problems of construction in high-temperature environments, balancing efficiency, safety, and environmental protection. Facing high-temperature challenges, choosing smart mist cannon machines enables efficient progress of open-air operations even in sweltering heat.

Contact With Us

If you have any questions please fell free to contact with us.